NYC Warehousing Blog | Storage & Supply Chain Tips

Blogs

Is Third-Party Warehousing Right for Your Business?

In New York, warehousing decisions turn into customer experience decisions fast. If you serve the NYC metro, you are operating near one of the nation’s biggest consumption markets and a major port gateway.

Comment contacter le service client Winner Casino en cas de problème urgent

Introduction au service client de Winner Casino Lorsque vous jouez sur winnercasino.fr, il est essentiel de savoir comment contacter le service client rapidement en cas de problème urgent, qu’il s’agisse de difficultés techniques, de questions relatives aux dépôts ou retraits,

Roby Casino mobile : jouer depuis smartphone ou tablette sans compromis

Une expérience de jeu optimisée sur mobile Aujourd’hui, la mobilité est au cœur du divertissement en ligne, et roby casino l’a bien compris. Jouer depuis un smartphone ou une tablette est devenu un réflexe naturel pour de nombreux amateurs de

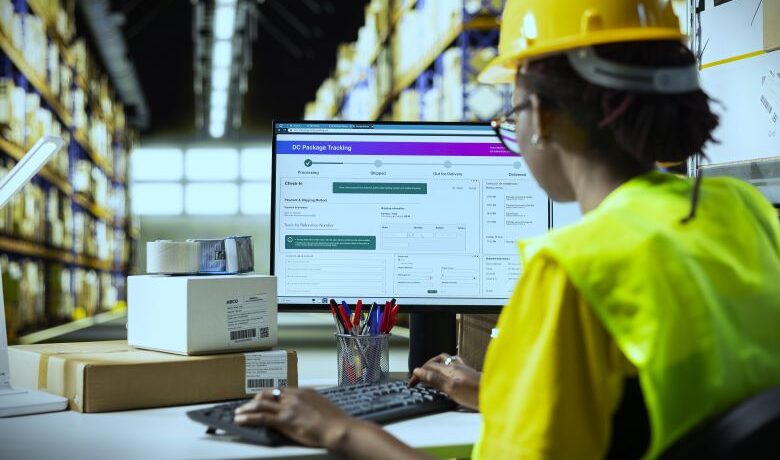

What Is a Warehouse Management System and Why Do You Need One

A warehouse management system is software that controls and coordinates how inventory moves through a warehouse, from the moment goods arrive to the moment they ship.

Bons plans et codes promos à ne pas manquer sur Pistolo Casino

Découvrez les meilleures offres sur Pistolo Casino Pistolo Casino s’impose comme une plateforme incontournable pour les amateurs de jeux en ligne. Grâce à son interface intuitive et sa large gamme de jeux, il attire de nombreux joueurs en quête de

What Is Nearshoring? Advantages for Lead Times, Quality, and Supply Chain Control

What is nearshoring? Learn the nearshoring meaning, benefits of nearshoring for lead times and quality, and the NYC warehouse role in control.

Sélection de jeux récents et innovants sur Happy Hugo Casino à tester absolument

Découvrez les nouveautés du moment sur Happy Hugo Casino Le monde des casinos en ligne évolue rapidement, et Happy Hugo Casino s’impose comme une plateforme incontournable pour les amateurs de jeux innovants. Si vous souhaitez découvrir des titres récents alliant

Top des machines à sous populaires chez Viggoslots Casino testé pour vous

Viggoslots Casino est devenu une référence incontournable pour les amateurs de jeux en ligne grâce à sa sélection impressionnante de machines à sous. Si vous recherchez une expérience captivante avec des graphismes de qualité et des fonctionnalités innovantes, ce casino

Offres promotionnelles Mad Casino : nouveautés et astuces pour en profiter

Découvrir les nouvelles offres de Mad Casino Depuis son lancement, mad casino séduit les joueurs français grâce à ses promotions innovantes et régulières. Les offres promotionnelles ne cessent d’évoluer pour répondre aux attentes des utilisateurs, proposant des bonus attractifs, des